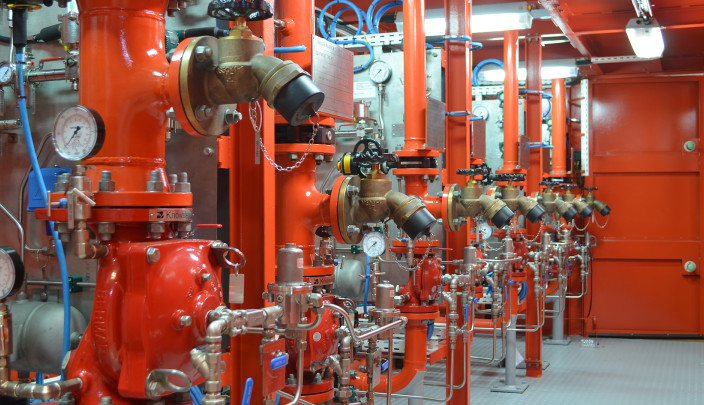

For this liquid gas, firefighting requires an entirely different approach to that chosen for other hydrocarbon products. In an LNG fire, the gas needs to be safely contained without the use of high volumes of cooling water being directly applied which can create adverse reactions. Consideration must be given to preventing a gas cloud from developing which can seek out an ignition source.

The radiant heat generated by an LNG fire is such that special consideration must be given to the material selection of fixed equipment such as the foam generators, the resultant volume of foam required must also be corrected calculated to ensure the correct cooling and coverage is achieved.

Our specialists have an extensive knowledge and resource of past experience with LNG liquefaction and re-gasification plants to ensure that the best possible advice is given.

Our approach to fire protection

Effective fire protection requires the right balance between your equipment and systems, your onsite capability, and the potential risks a fire can cause. At Knowsley SK, we employ a structured approach to help you find the very best solution to your fire protection needs.

Assess hazards, layout, processes & products

Our first step is to conduct a site survey, to assess the onsite hazards and the site layout, detail processes and evaluate stored products. Every site has a unique set of challenges which must be determined so that we can recommend the best solution. Our site survey will produce a detailed report with recommendations for improvements and may include a base outline of costs so that a scope of work can be agreed.

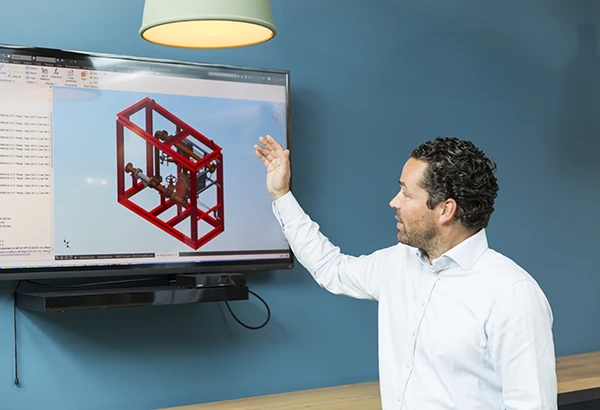

Initial design and costs

When a clear scope of work has been defined, we then begin with the initial pre-bid design works. This helps with the preparation of an initial cost estimate (quotation), which is then submitted to you. This typically leads to a technical evaluation phase, so we can give site disciplines or approved 3rd party organisations the opportunity to comment on the plans and suggest possible changes. Once all details are agreed, a final quotation is submitted, and the contract documents can be signed.

Smooth execution & maintenance

We assign you a dedicated Project Manager to act as a single point contract for all commercial and technical matters, helping to ensure a smooth execution process at all times. After the contract documents are signed, a full, detailed design and co-ordination with certifying authorities will be finalised. When any of our projects are completed, we will recommend a term maintenance agreement that includes all necessary testing. This helps us ensure your critical systems are always in optimum condition and provides you with absolute peace of mind.